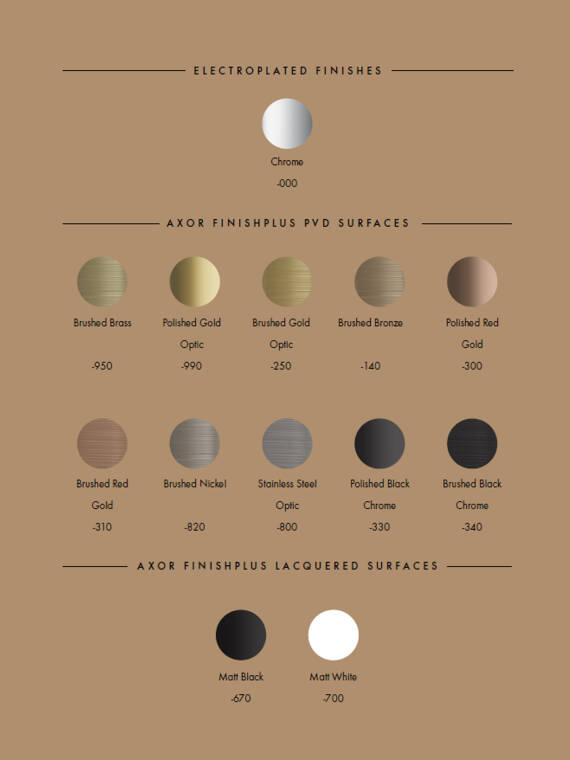

Refining the special with different surfaces technologies

Luxury is all about creating personal dreams. Colors are an essential part of fulfilling these visions. AXOR FinishPlus surfaces are an expression of individuality, setting new standards for luster, robustness and durability. Whether as single items or in large quantities, they are manufactured at the highest technical level and stand for quality made in Germany. Through a newly-improved lead time, with the most popular surfaces per collection and program being constantly in stock and the remaining finishes shipped within six weeks, AXOR FinishPlus ensures a more swift and convenient service than ever before.

Electroplating: The classic choice

Appreciated for its durability, universal color and brilliant sheen, Chrome has proven itself to be the sanitary industry’s finish of choice over the past few decades. Behind this excellent finish, however, is an equally remarkable technological process: electroplating. A complex chemical procedure that is continuously refined, electroplating is integral to providing all AXOR products their characteristic excellence in quality and timeless, classic appearance.

Electrochemical deposition of metals

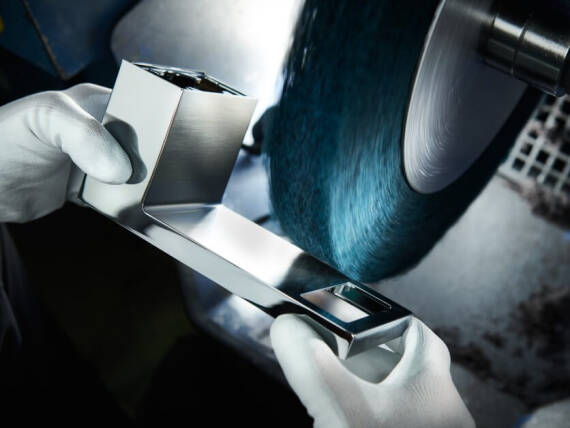

Electroplating refers to the electrochemical deposition of metals onto fixtures in an electrolytic acid. The process begins by polishing, then attaching the brass components of a product onto a rack before chemically cleaning the fixture’s unfinished surface in a supersonic bath.

First nickel, then chrome

Next, the fixtures are submerged in a series of electrically-charged chemical baths—first nickel, then chrome. The product is thoroughly rinsed with water after each bath to remove any remaining residues, and, as a final step, placed into a heat chamber to ensure even, stainless drying. Robust, impermeable and brilliant, the resulting Chrome surface offers a timeless standard finish that excels in any bathroom setting while also serving as a hardy corrosion-resistant base upon which further surfaces (e.g. PVD or lacquered finishes) can be applied

PVD: Brilliant color meets unmatched durability

Comprising a brilliant layer thinner than 1 micron, PVD (physical vapor deposition) finishes are exceptionally robust, durable and scratch-resistant while setting the standard for depth of color, surface quality and individualization.

PVD: Cleaned, brushed and coated

Before coating, each product's Chrome surface is adequately cleaned and, in the case of brushed finishes, roughly brushed to achieve a textured, adhesive surface. For polished finishes, PVD coats are directly applied onto a Chrome surface. Once prepared, each fixture enters a high-pressure vacuum chamber where several gases—specially blended to achieve the exclusive metallic AXOR FinishPlus surfaces—are physically deposited onto the product.

Finished in the vacuum chamber

Upon cooling on the product’s surface, the gaseous vapor condenses to form an ultra-thin metallic coat that leaves the unique texture of the underlying Chrome layer visible. Brushed or polished to perfection by expert technicians, each PVD finish is immaculately smooth and can withstand years of wear and tear.*

Laquer: An exciting addition to the AXOR FinishPlus portfolio

Lacquer surfaces impress with their strong colors, matt sheen and simple elegance—making them the perfect companion to the resplendent brilliance of metallic PVD finishes.

To ensure optimal paint adhesion before coating, each Chrome product is rigorously cleaned and its surface electrically charged inside a low-pressure plasma chamber. A subsequent blast of atomized dry ice removes any remaining impurities.

Each lacquer finish comprises either one or two layers, with the latter containing a separate adhesive base and colored top coat. Reflective of the brand’s restless pursuit of excellence and meticulous attention to detail, AXOR technicians continuously add just these paint formulas to ensure a consistent, excellent finish across varying color pigments and products.

How to order.

Upon request, almost any AXOR product can be personalized, customized and adapted via AXOR Signature services. The offering includes length adaption, engravings and labelings and complete new developments.

Trusted partners